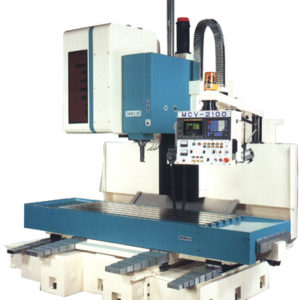

Model: M-1600

Type: VMC

Year: New

SPECIFICATIONS:

Table Size……………… 31.5″ x 70.8″

Table Weight Cap………… 5500 Lbs

Table Travel………..(X).. 63″

Cross Travel………..(Y).. 31.5″

Head Travel…………(Z).. 31.5″

Rapid Traverse………….. 420/360 IPM

Spindle Nose To Table Top… 6.7″ – 38.1

Spindle Taper…………… Cat 50

Spindle Speed…………… 4500 RPM

Auto Tool Changer……….. (24) Station (Arm Type)

Motor Size……………… 25 HP – 220V – 3 Phs

Weight…………………. 30,800 Lbs

Control Type……………. Centroid M-400

EQUIPPED WITH:

Automatic Tool Changer (24) Station (Arm Type)

Coolant System

Air Blast System

Halogen Work Light

Chip Tray

Auto Lube System

Spindle Oil Cooler

Leveling Bolts & Pads

Tool Box w/ Tools

Operations Manual

MACHINE FEATURES:

Centroid M 400 Control … (Mfg. In U S A)

(3) Axis Simultaneous Contouring)

Excellent Quality – “High Precision”

“Extremely” Rigid – Meehanite Casting

(4) Box Ways – “Y” Axis

X, Y & Z Axis … Hardened & Ground Bed Ways

Turcite Coated Ways

Class “7” Spindle Bearings

Metal Telescopic Way Covers (X, Y & Z Axis)

(1) Year “Machine Parts” Warranty

(1) Year “Control” Warranty

CENTROID CONTROL:

Mfg. In USA

(3) Axis (Simultaneous Contouring)

Full Conversational (Shop Floor Programming) & “ G” Code (Fanuc) Programming

15” Color Monitor

RS-232 & Ethernet Parts

(1) GB Solid State Hard Drive

2000 Blocks (per Second) Look-A Head Speed

OPTIONAL EQUIPPED AVAILABLE: P.O.R.

(52) pc. Clamp Kit

Mist Coolant System

Upgrade From 8,000 RPM To 10,000 RPM

28 KVA Transformer (440V – 480V)

(20) Pc. Cat 40 Retention Knobs

6” (Kurt Type) Vise w/ Swivel Base

6” Precision Kurt Vise

Chip Auger

Coolant Thru Spindle

Motor Upgrade 25 HP to 30 HP

SOFTWARE OPTIONS (CENTROID CONTROL)

Multiple Work Coordinate Systems

User Definable Macros & Sub Programs… Standard

Compression Tapping……………….. Standard

Unlimited Part Program Size

4th Axis Software…………………. Standard

Coordinate System Rotation

DXF In, CAD Drawing Input Software

Cutter Compensation……………….. Standard

Intercon Off-Line Conversational Program (For Desktop Pc)

Engraving Software

DIGITIZING & PROBING

2D & 3D Digitizing Software (Includes Mold Magic Software)

DP-4 Probing Package

TT-1 Tool Touch Off Kit

Tool Room Package

DP-4 Probing Package

TT-1 Tool Touch Off Kit

Work Coordinate System

ACCESSORIES:

(100) Step MPG

Installation & Set-Up…..(Per Day) … Plus Travel Expenses

Control Training…………(Per Day) … Plus Travel Expenses

COMMENTS: Control Mfg. In USA

“USA” IMPORTER, DISTRIBUTION & PARTS CENTER

Need a Part?

Have a Technical Question?

CALL: IMCO at 614-914-5087

F.O.B.: Location

TERMS: Check w/Order

All prices subject to change without notice